Sewing machines appeared in houses more than 100 years ago; couturiers Chanel, Schiaparelli and many others created masterpieces on them. All this time the industry has been actively developing, the size of devices has become smaller, the possibilities of use have expanded. In the 21st century, not only manual, but also electric devices, as well as machines with an integrated computer, are available to customers.

Diversity greatly simplifies the work of modern craftswomen. Right the selected device will save time and help with complex products. We reviewed the main characteristics of the machine and identified 10 determining criteria. High price is not always a quality indicator, each device serves specific goals. Will the craftswoman work regularly with different tissues or does she want a device just in case, if she needs it? A sewing machine for creating complex seams has functions that the device does not have for shortening and suturing clothes.

We examined the types of devices and the criteria that determine their application. But the seamstress is left to decide what it will be scribbling: jeans, fur, silk, lightweight fabrics or all together. Having defined the type and amount of work, having understood the characteristics of the machine, you can proceed to the selection.

Content:

Types of sewing machines

Which of the 3 types to choose

There are 3 types of machines on the market. We did not consider the outdated mechanical options that were received from grandmothers and remained in memory in the closet. Manufacturers are focusing on technology, so electromechanical, electronic and computer sewing machines are available to choose from.

Electromechanical

A feature of these devices is the combination of a mechanical system and an electric motor. The user independently sets the settings and modes that remain in the memory of the device. On such cars usually a lot of arms, buttons and levers. They are reliable and not very expensive, suitable for home use. They are chosen by novice craftswomen who want to learn all the functions. Such models are not capable of making complex seams, but they cope with all the popular operations.

Electronic

These machines are distinguished by a huge number of functions. They are equipped with an electric drive, the processes are automated and controlled by an electronic unit. The seamstress does not need to build the parameters independently, the characteristics already exist in the microprocessor. Machine itself right determines the criteria. The wizard sees the parameters on the display. Such models will suit both beginners and professionals. The downside is the high price. Not everyone needs so many functions.

Computer machines

The most advanced models. They are controlled by a program on a small computer. Such machines not only sew and sweep out loops, but also perform up to 500 types of stitching and greatly facilitate the work. For example, they signal a broken thread and automatically regulate the pressure of the foot. Computer machines are rarely bought for the home, so as The price is justified if the seamstress uses all the functions. And they are often not needed for beginners and even experienced craftsmen.

Types of lines

How to choose the number of lines

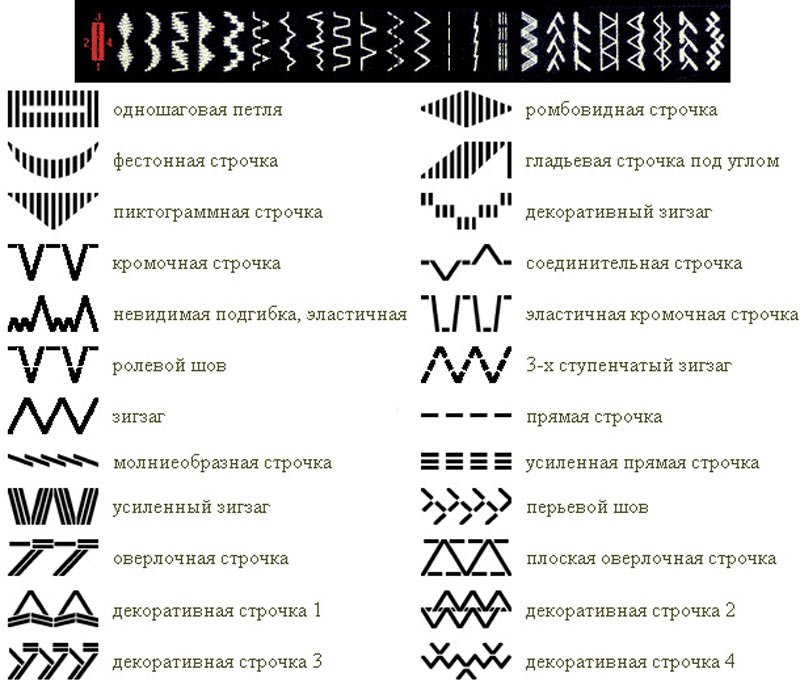

Modern sewing machines offer such a variety of lines that even professional seamstresses do not always know all the operations and how to perform them.Judging by the reviews on the forums, it is their number that is the determining factor for many skilled workers. However, we believe that a standard set will suffice for everyday use.

The most popular are straight and overlock stitches, for which a special foot is used. Zigzag is slightly inferior to them in the number of uses, but it will come in handy to many. The rest depends on the goals of the master.

Many machines perform double and triple lines. They allow you to make the seam stronger and imitate a thick thread when stitching jeans. They are used for stretching fabric to prevent tearing. Beginners are not very necessary, but in the studio without such lines in any way.

there is carswhich store additional operations in memory: sewing on zippers, making buttonholes, doing tints and darning. Rarely use the button processing function. To perform them requires special feet. Most sewing machines have options for overcasting and buttonhole dressing. The rest of the newcomers are not needed.

Shuttle type

How to choose the type of shuttleThe type of shuttle determines the use of the device. It largely depends on personal preferences and the operations performed. A shuttle is a hook that wraps a loop from the top thread around the bottom, moving around the bobbin. The formation of a seam depends on it.

Any type of shuttle is able to make a straight line. But there are 2 characteristics that greatly simplify the task. The category of the shuttle depends on them.

Movement type

This parameter determines exactly how the hook forms the stitch. There are 2 ways: rotation (rotational) and oscillation (swinging). The latter moves first in one direction, then in the opposite direction. Rotary revolves around the bobbin.

Any kind of hook will tangle the thread and ruin the work if the seamstress makes a mistake. Judging by the reviews of masters, there is no such device that will automatically do everything for the master. Therefore, the choice here depends on the personal preferences and skills of the seamstress. Any shuttle requires practice, at first tangled threads are obtained. Both types are suitable for home use.

Shuttle orientation

The shuttle can be vertical and horizontal. The first one is inserted from behind or on the side of the machine, it looks ahead. To some beginners it is difficult to learn the technique, they blame the design of the device. However, the reason for the approach. The horizontal arrangement assumes that the bobbin is inserted from above. However, the thread must make a turn of 90 degrees, which requires skills. As a result, you have to get used to any orientation, and professionals really do not like to relearn. Most will fit the vertical shuttle, so as it is less demanding on the quality of thread.

Loop processing mode

What loop processing to chooseOne of the additional parameters when selecting is the processing mode, without it the product will not be complete. Modern sewing machines are able to sweep over the hinges in semi-automatic and automatic modes. The latter is great for beginners practicing at home: it is enough to set the foot correctly and put a button in it. Then the craftswoman presses the lever, and the device does everything automatically. It remains to control the process.

Paws capable of looping in automatic mode work without marking on the fabric. They focus on the button, which captures the seamstress. On such machines there is a vertical lever that switches the movement of the device. It is located on the top and is used only for this operation.

Semi-automatic loops are not much different from the more modern counterpart, but require special knowledge from the master. The main difference is that the whole process needs to be controlled. The seamstress should manually turn on each of 4 consecutive operations and change the modes in time. To do this, set the handle on the typewriter.

The standard process of semi-automatic loops consists of several steps. The master sets the machine on the desired operation and lowers the foot. The first cycle can be started with any operation.But then the seamstress switches the device in time with the needle raised, changes the mode. A machine performs the operation in the opposite direction, the master stops the movement.

As can be seen from the example, in the semi-automatic mode, it is required to regularly switch levers. Beginners seamstresses may be uncomfortable, getting used to have longer. But a professional such a function is useful - the whole process is under control, you can always stop the device, fix the fabric, increase the distance.

Puncture force

What kind of puncture to choose for beginners and professionalsModern cars are equipped with an electric motor that drives the mechanisms. Complex equipment has several levers, but it is rarely installed at home. Budget models have an AC motor with a voltage of 220 watts. This is enough to work with light and medium tissues. Expensive devices have low voltage DC motors. They cope with any materials.

Machines with electric motors are united by one criterion - the strength of the puncture depends on the speed of sewing. The device works with fabrics of any density, if the master makes enough effort. To simplify the task, manufacturers began to install needle force puncture regulators. With it, the machine can sew both light and coarse fabrics, without forcing the master to try so much.

Beginners often pay attention to power, believing that the density of the fabric with which they can work depends on it. The importance of this factor for budget cars, we consider below. Expensive devices allow you to adjust the puncture force. In addition, manufacturers often write power, which is several times higher than the mechanical. The maximum value on the market now have devices Singer.

The strength of the puncture depends on the speed of sewing. For home use Beginners will come up with models that allow you to smoothly limit this value. However, these machines are much more expensive. Some manufacturers, including Brother, offer to sew without a pedal. Judging by reviews professionals, they lack control. And beginners like to press a button and wait for the result.

Paws

How to choose the legs

It is impossible to sew without pads, so all the machines have at least a couple of basic options included. More expensive devices offer more interesting choices. Standard legs include universal, straight-line for looping and zippers. Special options are able to create satin stitches, cords, hidden stitches, darn and more. Below are the most popular legs, which are recommended by experienced craftswomen:

-

For assemblies. With its help it is more convenient to do the gathered lines, the density is regulated by the tension of the threads and the stitch width. The denser the fabric, the less noticeable the result.

-

Walking. Allows you to grind several layers, most often used for patchwork and quilting works.

-

Teflon. Designed to work with genuine leather, leather and coated materials. Some seamstresses use a roller foot, which allows you to move the fabric forward at the right intervals. She also deals with mantle and jacket fabrics.

-

With a snail. Allows you to sew an oblique bake without manually tacking it. The seamstress is enough to cut the fabric along the oblique, tuck in the foot and sew. Of the additional options, it is considered the most useful.

Judging by the reviews of experienced seamstresses, each foot has recommendations on the width of the fabric and its density. If you do not take them into account, a surplus of material will lead to crushing.

Sewing needles

How to choose a needle on the type of edge

The main characteristic of the needle is the tip. First, the master is determined with this parameter, then it considers the thickness. The standard tip can be pointed and rounded, but the manufacturer offers dozens of additional options to choose from. We reviewed the most popular:

-

Pointed. Suitable for most synthetic fabrics. There are 7 popular sizes - 60/8, 70/10, 80/12, 90/14, 100/16, 110/18, 120/20 - which is enough for all common materials.The first digit indicates the diameter, the second - the type needles.

-

Rounded. Most often used for knitwear, suede, fleece and knitted fabrics. The tip spreads the fibers, not stuck into them. This needle is included in the standard set and is in the house of every craftswoman.

-

Stretch It is called so because of the ability to sew materials containing Lycra. It is used when working with underwear and swimwear. Such needles have a small groove near the ear, so as not to miss the stitches.

-

For jeans. Used not only for this material, but also for any dense tissue. They are distinguished by penetrating ability.

-

For the skin. The tip of the needle is sharpened to penetrate the product without damaging the material.

-

For microfiber. It best copes with dense thin tissues. Able to create straight stitches and loops.

-

For quilting. It features a long point and a small peephole to easily pass through several layers of material.

There are double and triple needles, mounted on a nylon block, with wide ribs and crevices in the eyelet. They are used for decorative stitches and complex techniques (embroidery at low speed for a small amount of time). Beginners and even experienced professionals usually need such needles.

Motor power

How to choose the right powerPower in sewing machines is not as important as in other technology. Cheap options have indicators from 60 to 100 watts. The maximum material thickness depends on this, if the manufacturer has not added a puncture force regulator. With him power is almost irrelevant.

When choosing a budget model, the appropriate parameters are 70-80 watts. In electronic machines, indicators may be lower than in mechanical ones. They do not need to use so many mechanisms and nodes, so great power is not needed. The footswitch also plays a role in determining power ratings. In inexpensive models it is of 2 types:

- Hot, with rheostat control. When working with thick fabrics, the seamstress needs to push the pedal harder to increase the needle puncture. The speed rises, which prevents novice skilled workers. In addition, the pedal is very hot, the engine runs faster. This leads to premature wear. sewing cars. For home use mechanical devices are not very suitable and are considered obsolete. However, buyers of such devices are encouraged to choose high power.

- Cold, with electronic regulator. Allows you to press the pedal an unlimited number of times, the machine is controlled automatically. When a seamstress works with a thick cloth, the electronics take more power and increase the puncture rate. No need to press the pedal many times. Power characteristics are practically unimportant, 60-70 W is enough for most fabrics.

The only thing that warns users of electronic machines - do not take too thick cloth. It blocks the needle, the power rises excessively and the device fails. Machine manufacturers houses The instructions indicate the density limits of the fabric.

additional characteristics

What feature is recommended to consider when choosingThe minimum set of functions for the machine for the house includes a straight line, zigzag for processing edges and loops. However, most devices have several additional features. We reviewed the most popular and figured out who they might need:

-

Foot pressure adjustment. It is carried out with the help of a spring in budget models and automatically in more expensive ones. The foot rises to a height of 12-15 mm for sewing thick fabrics.

-

Thread tension adjustment. The most beautiful stitch is obtained with a uniform weave of the upper and lower threads.Their tension in some devices is automatically adjusted. Modern computer devices are able to determine the density of the fabric and set the correct values. Inexpensive options are equipped with a trimmer screw on the hook, which adjusts the master.

-

Sewing speed Sometimes manufacturers add protection from jerks, that is, the pace of work gradually rises and falls. Some companies, including Janome, Husqvarna and Brother, use the start and stop button. Others prefer levers.

-

Automatic trimming strings. Allows you not to reach for scissors. It helps when working with products where there are many short stitches.

-

Upper conveyor fabric. This device is attached to the foot and helps to cope with thin and sliding materials. Some manufacturers, including Pfaff, equip almost all devices with a conveyor, it cannot be removed. Other brands allow you to purchase an accessory separately.

-

Sewing advisor. Modern devices are equipped with a system of help and tips. The adviser says which foot to take for a specific operation and in the pictures shows how to use it.

Optional accessories

What accessories are needed for sewing

Included with the sewing machine are basic accessories, designed to test the device and help you master the standard techniques. Then the seamstress re-purchases needles, bobbins, legs and other tools. It is practically impossible to do without them, the standard configuration is not enough for long. We reviewed the most popular accessories and how to use them:

Yarn

Hand sewing threads are not suitable for machines. The correct materials are made from stronger polyester fibers. They are distinguished by low shrinkage, they perfectly keep the given shape. When you pull the correct thread through the needle, it does not shag and break.

Spools

The bobbin paired with a needle produces the correct seams. The standard kit includes several options, and experienced seamstresses say that the more the better. Spools often break (especially plastic) and are lost.

Butter

Machine parts are in constant motion and experience increased load with regular use. If oil is not lubricated in time, the conveyor will stall and the needle will begin to walk more tightly. Many manufacturers recommend a particular brand in the user manual.

Upper conveyor

Allows to cope with naughty slippery fabrics. He promotes material layers at the same rate. Without it, the bottom layer of fabric will be slightly ahead, leading to sagging.

Over time, the master may need mats to machine non-slip, guides, soles of the upper conveyor and more. However, a beginner is enough a couple of the above accessories.